|

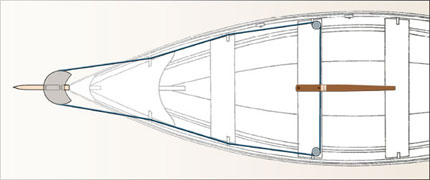

The Plan:

-

March 25, 2018

The plan is to make the sailing modifications first and then build the cabin.

The cabin's location in the aft end of the boat will especially effect

how the rudder is controlled. Looking at the conversion for sailing,

item by item, here are some of the details. By the way, this is all my

way of 'thinking out loud', so to speak. My way of putting my thoughts

in order so I can be fairly efficient when actually working out in the

shop.

I'll be updating this page as the design process unfolds.

RUDDER/SKEG:

Rudder hardware was ordered from Duckworks early so I will have the

gudgeons and pintles in hand when doing the final design work for the

rudder. Here is my preliminary design for a kick-up rudder based upon

work done by Paul Riccelli at Riccelli Yacht Design.

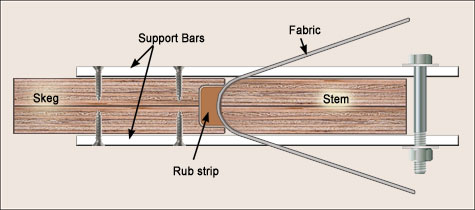

I have chosen to build a laminated plywood skeg for the kick-up rudder

to fasten to. Primary support will be two pairs of 1-3/4" x 1/4" rigid

fiberglass straps that fasten the skeg to the stem.

The forward edge of the skeg is routed to fit snugly around the stern

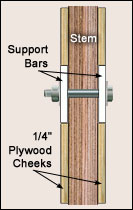

rub strip. The support bars will pass through slits in the skin (cut &

shaped with a hot knife) and will be bolted together as shown. I plan on

gluing 1/4" plywood 'cheeks' to the stem above and below the support

bars to help keep them in place. The reason for this system is that this

is a very tight area with no opportunity to screw or bolt the supports

directly to the stem without making many holes in the skin.

The

rudder will be made up from two pieces; the upper, rudderhead, will

be

attached to the skeg with stainless steel gudgeons & pintles, and the

lower part attached to the upper by a 3/8" pivot bolt. The cheeks of the

upper piece are to be lined with HDPE to reduce friction.

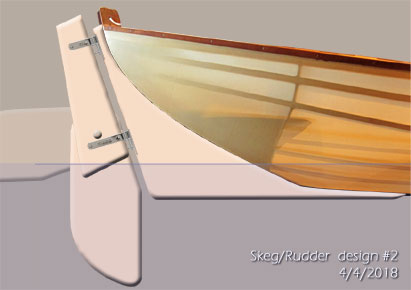

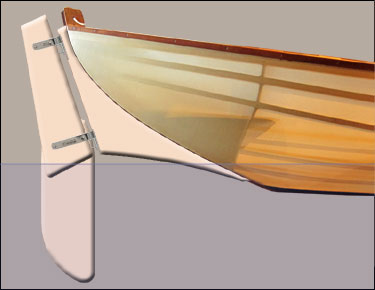

Design #2 - April 4, 2018

Design #1

I liked the looks and smaller size of design #1 but remembered that it

might be nice to have a functional skeg even when not sailing. Design #2

does that and also would be stronger since I can put a couple of SS

screws up into the keel at the forward end of the skeg. With the rudder

removed while rowing the skeg will give some directional control,

hopefully helping when rowing on windy days. It is also possible that I

may want the rudder installed on those days if the skeg doesn't function

as I hope. In that case it might be nice to add foot controls for the

rudder.

Speaking of controlling the rudder, the plan is to install a small,

maybe 5" radius quadrant atop the rudder head and have stainless steel

cables lead forward along the outside edges of the cabin leading to the

mid-ship tiller. The tiller will be mounted below the thwart and hinged

and/or removable for times when it's not needed.

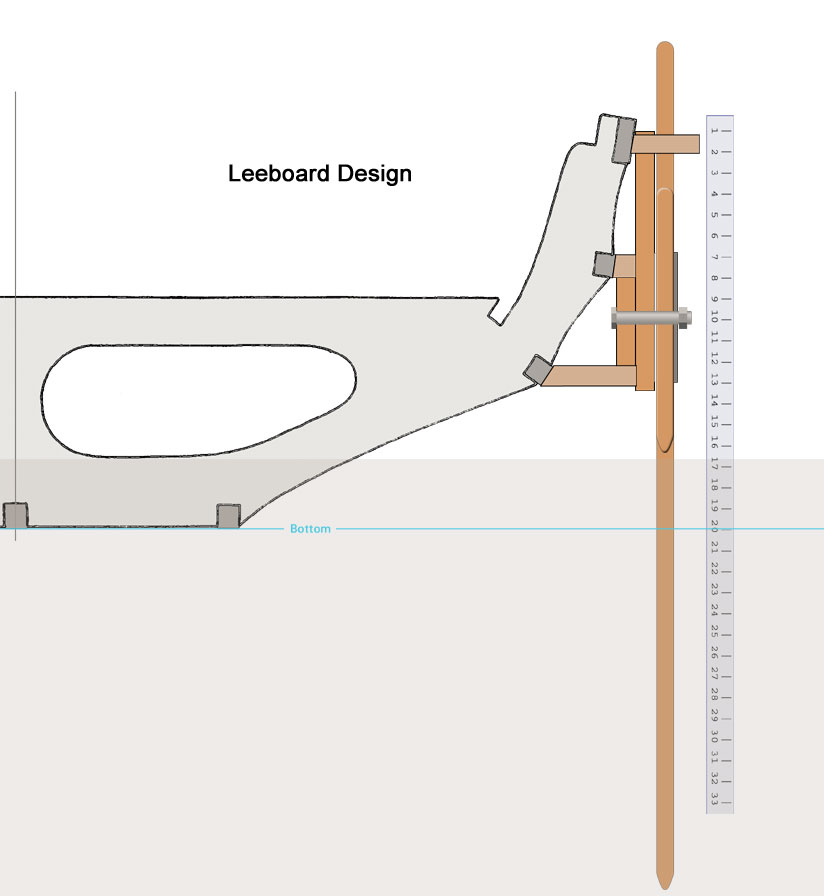

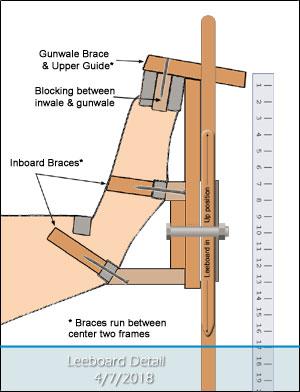

LEEBOARD:

I've been in contact with Dave Gentry who designed our skin-on-frame

dory regarding this series of modifications and generally he's OK with

them but suggested that a daggerboard might be better than a leeboard

for this boat, and he may be right. I believe his concern is based upon

the lack of framing to support the stresses imposed by a leeboard, which

can be pretty strong.

My concern with a daggerboard is having a hole in the bottom of the boat

and that daggerboards can't kick up when they

strike something like a submerged log or rock ledge. The force of that

sort of impact would have to be absorbed by the daggerboard trunk and

ultimately by the framing of the boat.

So my solution to this dilemma is to mock up a leeboard support

structure and see how it feels when applying lateral forces to it. If it

feels OK, that is, if the framing of the boat appears to be able to

handle the loads, I'll go ahead and build the real thing. If not, I will

switch gears and design a daggerboard trunk with some sort if passive

shock absorber.

SAIL:

I ordered a sail kit from Dave Gray at

PolySail International. After reading

many reviews and recommendations I decided to make the sail from

polytarp material; but not the cheap, flimsy, ugly blue tarps from the

hardware store. Dave Gray has done his homework and sourced some nice

low-cost, high performance poly laminate white tarp material and

assembled several sized kits for making your own sail.

I purchased the 'Medium PolySail Essentials Only Kit' that includes a

12' x 16' white tarp, double-faced tape and rope for around the edges of

the sail and a brass grommet setting kit with 24 grommets. Sue and I

will be sewing all seams with heavy white polyester thread.

The sail design is a 76 sq. ft. balanced lug with two reef points. We

added a walking foot attachment to our venerable Husqvarna/Viking

Emerald 116 sewing machine since the material is so thin and smooth.

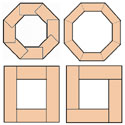

MAST & RIGGING:

With a basically tippy boat like this it is important to keep the weight

aloft as low as possible so I'd like to make a hollow wood mast with the

yard and boom being solid wood. There are several ways to make a hollow

mast; birdsmouth, coopered or box-section. The mast will be tapered so

that complicates it a bit. I'm waffeling - but like the idea of a

coopered mast ( top right) because it uses so much less clear wood and

has the potential to be very light. I'll have to do some research to see

if there is an easy way to make a tapered coopered mast. On the other

hand, a solid mast that is properly shaped can be stronger. What to do?

Latest News!

May 19, 2018 - Skeg & Rudder

The weather is cooperating and we now only need to heat the shop when

expecting epoxy to cure. I am now working on the finishing up coating

the bearing surfaces of the swing-up rudder with epoxy filled with

graphite powder. The idea is to reduce friction between the rudder blade

and the cheeks of the rudder head. Prior to this step I bored a 3/4"

pivot hole hole through the pieces and in the photo below have filled

those holes with graphite and silica thickened epoxy. When it has cured

I will re-drill 1/2" holes through the centers for the 1/2" x 2-1/2"

stainless steel pivot bolt.

|