|

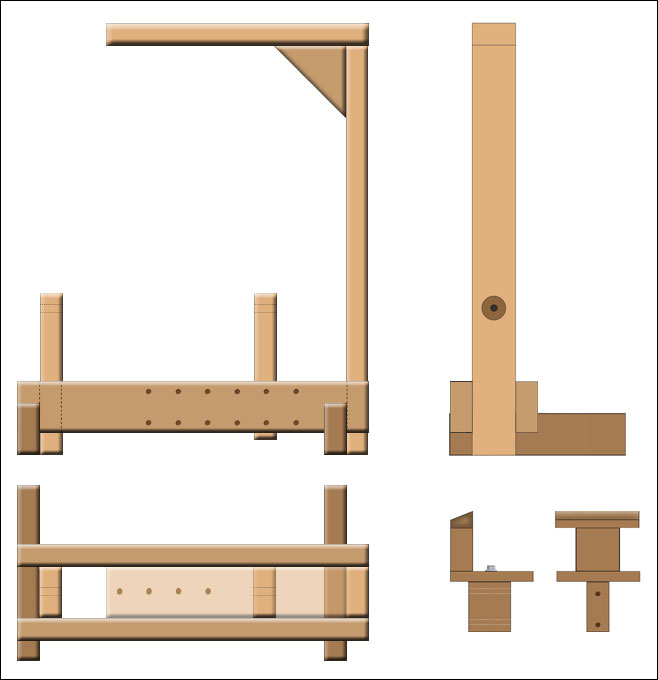

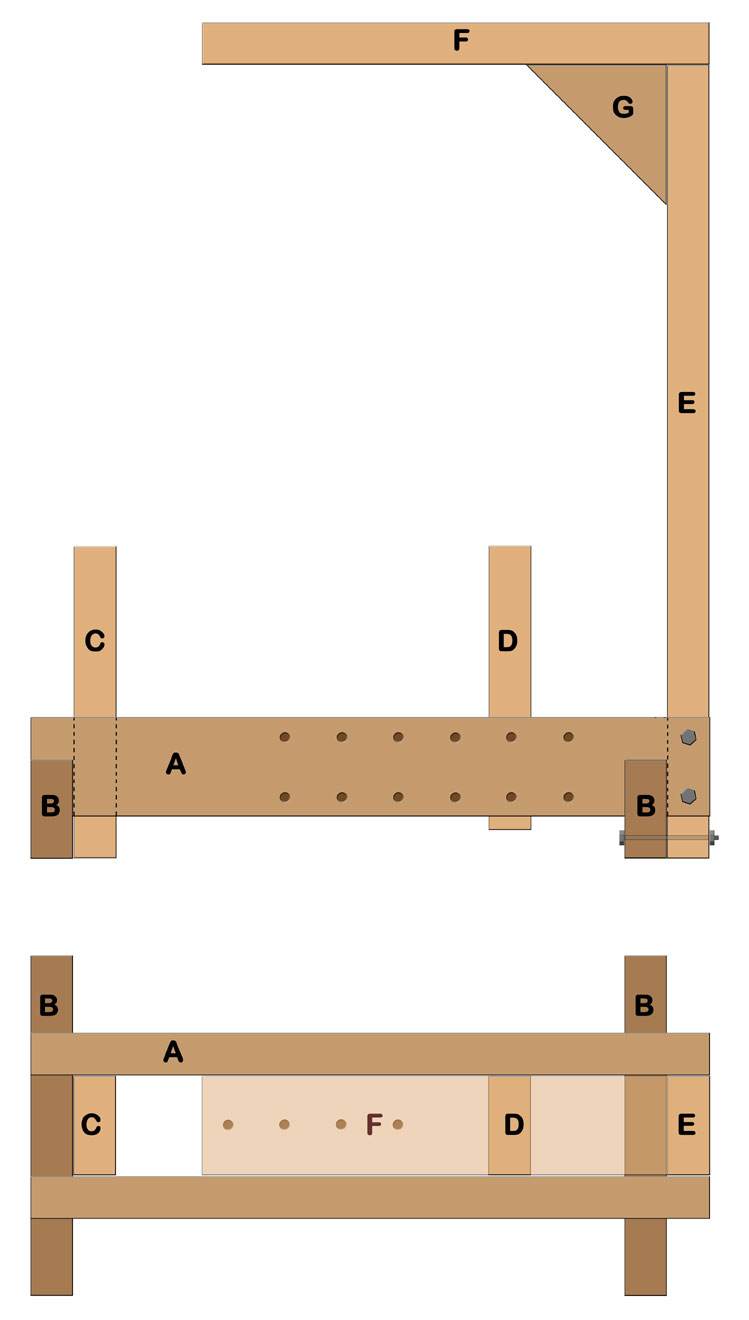

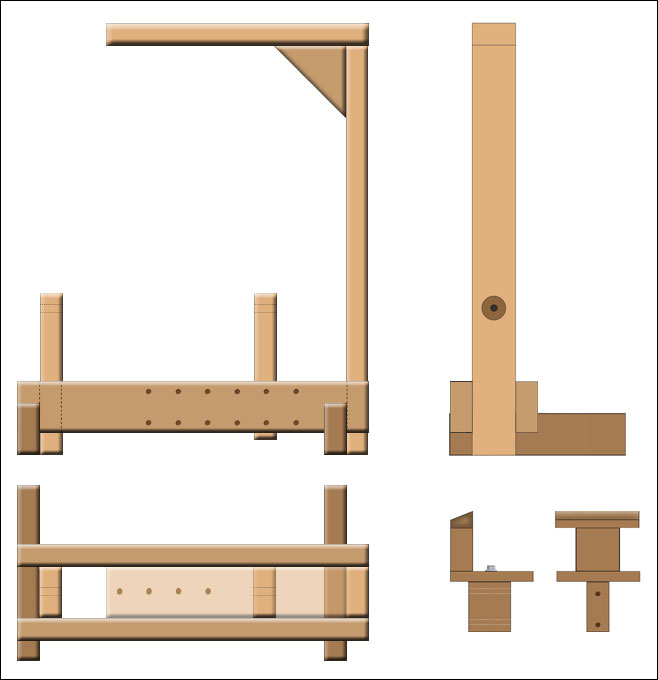

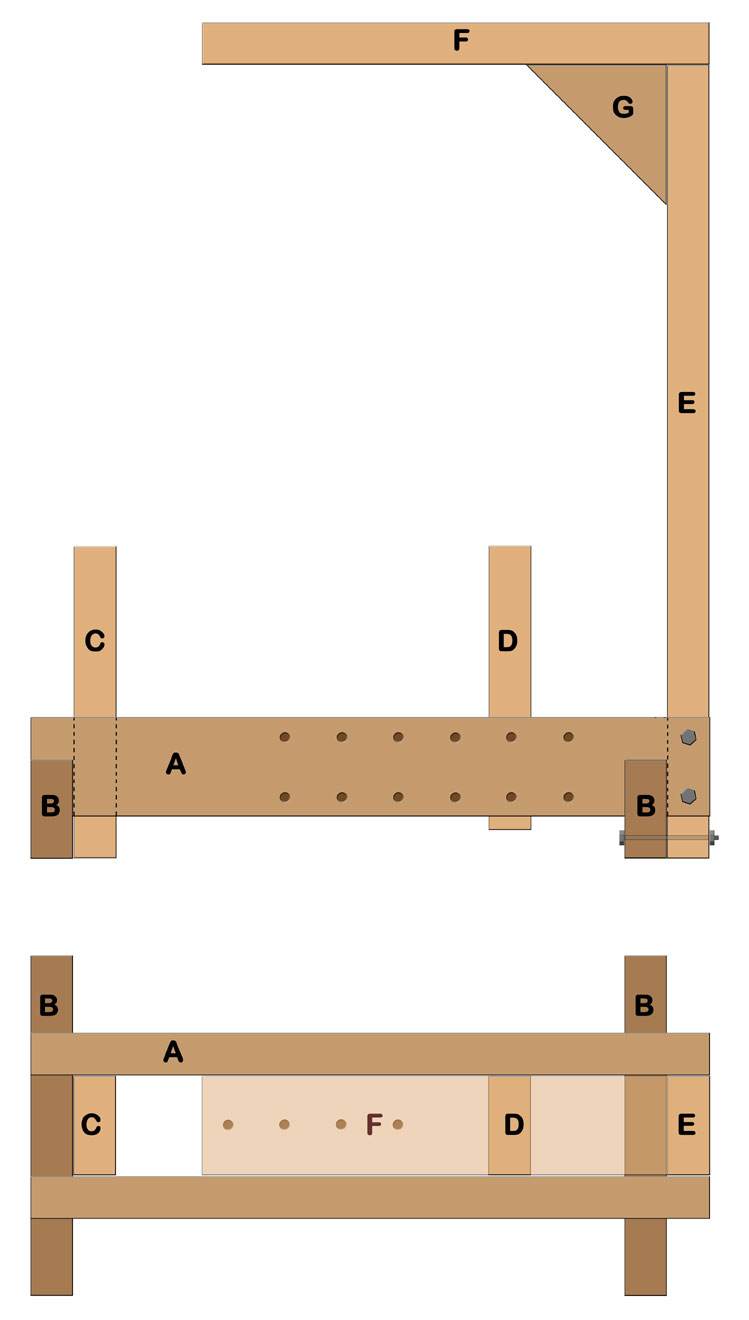

Lathe Layout:

Dimensions & Cut List:

All from nominal 2x4 (1-1/2" x 3-1/2") stock.

A - Ways

24" (2)

B - Base

12" (2)

C - Fixed Left Tailstock 11"

D - Movable Right Tailstock 10"

E - Riser Beam

28"

F - Cross Beam

18"

G - Gusset

5"

Parts A, B, F & G = 95"

Parts C, D & E = 49"

General Construction Notes:

- 2x4's should be clear (or

nearly so) and very straight - especially with no twist.

- Base unit

(parts A, B & C) are assembled with 2-1/2" x #8 deck screws and

wood glue. Pilot holes should be pre-drilled to prevent splitting.

-

Clamp pieces in position then drill.

- Movable tailstock (D) is cross

drilled to match holes in ways and pinned in place with 2 - 3/8" x 8"

bolts with the threads cut off.

- Upper unit (parts E, F & G) are

screwed & glued like base unit was.

- Holes in Ways (A) are 2" on

center beginning 9" from left end - 3/8" diam.

- Holes in cross beam

(F) are 2" on center beginning 1" from left end

- Riser Beam

(E) is bolted to

base for portability with 2 - 3/8" x 7" bolts and 1 - 3/8" x 5" bolt.

The Building Process:

Begin by sawing two 2x4's into the nine pieces as shown above. A

nice touch is to round the tops of parts C & D and now is a good time to

drill the holes in those two pieces for the lathe centers.

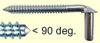

Lathe Centers: I had good luck using

a medium duty gate

pintle (1/2" diameter) for the adjustable lathe center and a 1/2" x 3 lag bolt for

the fixed center. Bore a slightly undersized hole through the tail stock

upright, heat the pintle or lag

bolt with a propane torch (holding it in Vice Grips) and quickly screw it into the

hole. This burns some decent threads into the hole. While the screw is

still warm rub some bee's wax on it for lubrication. One of the

first turning projects on my lathe was to turn a wood handle to slip

over the 'handle' end of the pintle. I filed a nice, smooth, bluntish

point on the working end of the screw. This setup worked well for a lot

of years.

diameter) for the adjustable lathe center and a 1/2" x 3 lag bolt for

the fixed center. Bore a slightly undersized hole through the tail stock

upright, heat the pintle or lag

bolt with a propane torch (holding it in Vice Grips) and quickly screw it into the

hole. This burns some decent threads into the hole. While the screw is

still warm rub some bee's wax on it for lubrication. One of the

first turning projects on my lathe was to turn a wood handle to slip

over the 'handle' end of the pintle. I filed a nice, smooth, bluntish

point on the working end of the screw. This setup worked well for a lot

of years.

This is also a good time to drill the tailpiece

securing holes in the ways. Easiest way is the clamp the ways together and

use a drill press to bore through them at the same time - nicely

aligned. Mark and cross drill the tail stock (D) to match all those

holes you just drilled in the ways.

Notch the ways to fit

over the base pieces (B). Assemble the base section securing everything

in place with clamps. When you have it all lined up and square,

drill one pilot hole at a time and put in a deck screw. By going at it

one screw at a time you give yourself multiple opportunities to check

and re-align the base unit. The way I drill these kinds of pilot holes is

to first drill using a small (~1/8") bit to almost the depth of

the screw, then use that hole as a guide to enlarge the hole with a bit

that will allow the screw to just slide through the hole without

snagging. Finally, use a countersink bit to allow the screw head to be

flush with the surface. Three steps that go a lot faster if you have

more than one hand drill but I usually just change bits - over and over.

Now, drill the holes in the upper cross beam. These holes give

you multiple spots along the length of your turning to fasten the cord

or strap that wraps around your work-piece.

Assemble the upright pieces (E, F & G) with clamps and screw them

together as you did the base unit. It would be a good idea to remove the

gusset and apply some good wood glue and re-assemble it. The screws will

make it unnecessary to clamp that awkward shaped piece.

Just

three more holes to drill; two crosswise through the ways and

lower end of the upright, and one through the very lower end of the

upright and the base piece - see the drawing. By bolting the two main

units together rather than screwing and gluing, you can easily take the

lathe apart for transport.

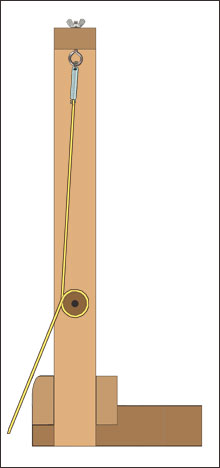

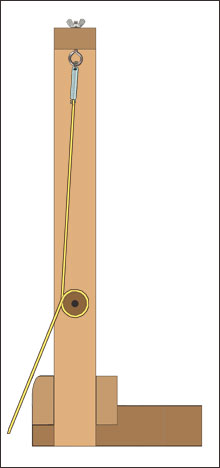

The only thing left before you can

begin turning your first piece is the cord or strap that makes the

whole thing work. To create the reciprocating action you can use a metal

spring, perhaps a section of a screen door spring, or a piece of bungee cord.

This recoiling device fastens to the screw-eye and the wrapping cord or

strap fastens to

it, coming down to wrap once around your

work-piece, and then continues down to a loop or better, a flat board

that acts as a treadle. A nice touch is to round over the front edge of

the front way to help reduce wear on the cord or strap.

In the

lower right corner of the Layout image is my idea of how one might make

an all-wood tool rest from the left-over pieces of 2x4. Its base fits

between the ways and can be adjusted left and right to align with the

holes in the ways. The horizontal piece is fastened to that base by a

bolt with a nut that is imbedded in the base. This allows the tool rest

to rotate laterally. You may well come up with a better way to do this

but what I've presented is very similar in function to the tool rest

I've used on my treadle lathe for years.

Using the Spring Pole Lathe:

The biggest tip I can offer is to keep your lathe tools really

sharp. On some of my tools I have ground a shallower bevel and that

seems to work well especially on green wood. It does take a few minutes

to coordinate foot action with a very slight backing-off of the tool on

the spring's return stroke, then a slight moving forward of the tool on

the down stroke. This movement become second nature quickly.

If

you have any questions please use the contact page and I'll do my best

to help you out. I hope you enjoy using your new lathe!

Steve

|