|

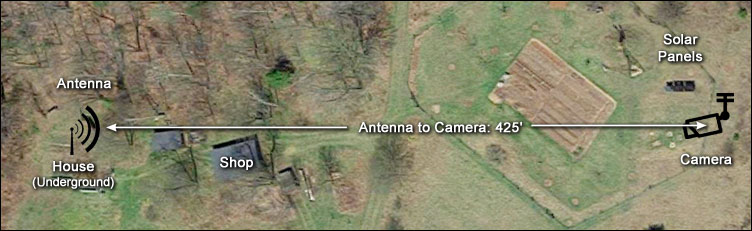

Setting the stage:

Our original solar

panels were mounted on or near our house but it soon became apparent

that the maple trees south of the house were blocking the sun –

especially in the winter when we needed power the most. What we were

after was a spot to relocate the panels that had dawn-to-dusk direct sun

all year round. The closest spot is over 400’ east of the house, near

our water pumping windmill.

Normally it would not be economical

to try to transmit low voltage DC that distance without significant

voltage drop; the cables would need to be large and expensive.

Fortunately we managed to obtain, as salvage ($50), about a quarter mile

of 100-pair phone line. This cable is about 1-1/2’ in diameter including

its significant shielding and insulation and we had a couple of segments

that were well over 400’ long. I stripped each of the 200 ~19 ga. wires

a couple of inches, stuffed them into a short section of copper tube,

hammered the tube flat and flowed solder into the joint – on each end of

two cables – 800 wires to strip, all together. I then drilled a 3/8”

hole in each connector and celebrated!

We ran these cables on top

of the ground from the new array location to a spot just outside the

house. Over several years we buried the cables to protect them from us

and our inclination to try to mow too close to them. Over the years, (we

installed our first 32 Watt Arco panel in 1981) the array has grown to a

bit over 1000 watts and runs at 24 volts DC. Voltage drop is minimal and

actually somewhat protects our older 50 Amp MPPT charge controller.

Solar array and camera box

Enter the PanelCam:

Every morning in winter we would look out towards the array

and try to guess if there was enough snow on the panels to warrant

getting dressed for the cold and trekking out clean off the panels. We

can see the array from the house but since it is directly east of the

house we can only see the edge of the solar panels. We have long

considered, half joking, installing a remote camera, aimed at the front

of the array but dismissed the idea because of cost and in truth, we

didn’t mind those early morning walks all that much.

Before I go

any further I should come clean on another point. I have not had a lot

of glowing success with electronic projects in the past, having smoked

several circuits including a homemade solar panel tracker. But I had

been reading about Arduinos. Those small microcontrollers were designed in

Italy to help young folks learn about electronics and programming. Since

I wouldn’t have to invent my circuits from scratch I figured that I

might have a chance with those little guys.

The PanelCam project

is made up of two separate systems; 1) inexpensive Wi-Fi ‘security’

camera and 2) a circuit that would switch the camera on when needed and

off when not – which is most of the time. The reasons for this are that

because of its remote location the camera needs to be battery powered

and more importantly, if the camera was on and connected to the Internet

all the time it would blow our limited Internet plan into overtime, many

times over.

FunLux Wi-Fi Camera

I found a reasonably priced ($35) ‘FunLux’ Wi-Fi

camera that has an external antenna and can run on 5 volts DC. I have

mounted the camera in a mostly weatherproof enclosure on a fence post

out in the garden. To increase the range of the camera I also installed

a small, 6” square, parabolic reflector with the antenna right at the

focal point of the reflector.

The Cantenna:

Two

antennas on house roof - 'Cantenna' on right

At the house end, because our router is inside, below the

earth-covered roof, I installed a TP-Link Wi-Fi Extender that also has a

single external antenna. This unit is connected via 6’ of expensive

low-loss cable to a homemade, very directional ‘Cantenna’ that aims

right at the camera enclosure – line of sight with no obstructions.

Other than constructing the cantenna, phase one of the project went

pretty quickly. Here’s a brief rundown on the cantenna construction

which is totally borrowed from a couple of web sites.

Cantenna constructed from old Thermos shell

My research

showed that to build this antenna I would need a can about 3-5/8” in

diameter and 7” tall but I was unable to find a can that size in the

grocery store. I did have the shell of an old thermos bottle that I

ended up using. Here are a couple of photos of the first try with the

thermos. I subsequently refined the thing by soldering on a new, flat, shiny

bottom and moved the placement of the receiver wire a little. A little

paint and a cover to keep out the snow and it was ready to go.

The Switch Circuit:

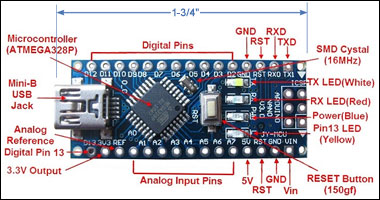

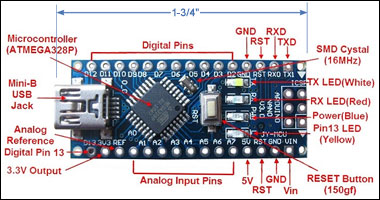

Arduinos

(pronounced like: are-‘Dween-ohs) are cool! They’re small

microcontrollers capable of handling multiple inputs and outputs, draw

very little current and with the addition of battery are totally

independent little units. They are programmable, meaning with a few

instructions you can have it do your bidding. I began with a common Arduino

Uno, about $24 for the original Made in Italy version. The neat thing is

that the source code for the microcontroller boards and everything else

about them is officially ‘Open Source’. Because of space constraints I

chose to use a couple of smaller Arduino Nano clones that cost around $4

each.

Arduino Nano layout - (note size)

Arduinos are

programmed using versions of the ‘C’ and ‘C++’ languages and a free,

downloadable programming environment (IDE).. Although I have been

programming computers starting back in

1975 on an IBM 5100 mini computer and subsequently using a few other

programming languages, I had never done anything with ‘C’ before.

(As an

aside, that IBM 5100 cost my employer about $16,000 with 16 MB of

memory. We upgraded it to its maximum of 64 MB (yes, that’s megabytes!)

at $1,250 per each of three memory boards. That’s in 1975 dollars.)

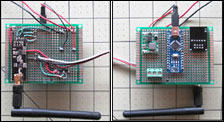

Basically what I did was hook up a Wi-Fi transceiver to each of the

Arduinos and then configured the circuits so one, the one at the house,

is the transmitter, and the other, the one out with the camera, as a

receiver.

The Transmitter:

The

unit in the house is set up with a simple push button, and a bit of

code, to send either an ON or OFF message to the receiver. This unit’s

Wi-Fi radio is connected to a 6’ low-loss cable

designed to be used with 2.4 GHz devices. On the far end of that cable

is the transmitter’s original little ‘rubber duckie’ type antenna with

its own parabolic reflector. This is mounted inside a small weatherproof

box and aimed at the camera box out in the garden. The transmitter and

the Wi-Fi Extender are each powered by their own DC-DC buck converter.

The transmitter runs on 7 volts DC and the extender on 9 volts DC. The

transmitter also has a small 4-line LCD display that confirms that the

signal was sent & received OK and as a bonus, shows the temperature out

at the camera box.

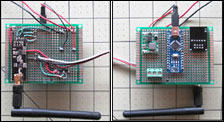

Receiver circuit board

The Receiver:

This unit is mounted in the lower part of the camera box with its

own directional parabolic reflector aimed back at the house. When the

receiver gets a valid ON or OFF message it confirms this by sending a

quick little ‘ack’ message back to the transmitter. And cool enough, I

programmed it to tack the temperature onto that message. When it

receives an ON message the Arduino activates a small relay that sends

power to the camera and simultaneously lights up a pretty bright LED

that we can see from the house to confirm that all’s well and the camera

is indeed ON. An OFF message does the opposite and the OFF state is

confirmed by the LED being OFF.

View from the PanelCam

Operation:

If there is any chance that the panels might have snow on

them I flip a switch at my desk that turns on the power to the Extender

and transmitter. I then go over to the ON/OFF button and press it a

couple of times so the camera cycles on and off and then ends up ON

according to the display. I probably should refine this a bit in the

code but for now the temperature only shows correctly if the receiver is

cycled on & off & on again. I’d rather it didn’t need to do that but I

can live with it for now.

LCD Display shows camera

status and temperature at camera

I wait a minute or so for the extender

to boot up and for our router to find it. Then I fire up the FunLux app

on my Kindle Fire HDX 8.9 tablet and if all went well I can see a nice

HD snapshot of the array. Another click and a live HD video of what’s

going on out in the orchard displays. This works well much of the time

but sometimes the FunLux app shows “Device Off Line”. I then usually

force-close the app and try again and usually the system works as

planned. In the app you can turn the infrared night lighting on or off

and the images in night darkness are surprisingly clear though of

course, colorless.

Summary:

What might I do differently?

1) I might just buy

a little TP-Link 9 Db external antenna, about $21, to use in place of

the cantenna. It was an interesting sub-project but it took me nearly a

month to build and fine-tune it.

2) I might shop around for a

different camera. The camera seems to be working fine but the FunLux app

is a bit clunky and at times totally unresponsive. Unfortunately, I

think I’m stuck with that app but if you know otherwise, let me know,

OK?

Cost breakdown for the whole system:

• Camera, FunLux 720p

HD … $35

• TP-Link WiFi Extender … $20

• Arduinos Nano Clones (2)

… $8

• nRF24L01 (+) wireless Transceivers (2) … $11

• 6’ Low-Loss

antenna cables ~ $25 ea. … $50

• 4-Line LCD Display (Frentaly) … $13

• 2-Chanel relay (SunFounder) … $7

• DC- DC converters (4) ~$10 ea …

$40

• Waterproof DS18b20 Temperature sensor … $3

• Misc. perf

board, wire & solder … ~ $15

Total (Unless I’ve forgotten something)

… $ 202

|

|

Code for the Transmitter:

// PanelCam Switcher TX using AckPayload - the

master or the transmitter //

// By Steve Schmeck 1/27/2017 //

#include <LiquidCrystal_I2C.h>

#include <SPI.h>

#include

<nRF24L01.h>

#include <RF24.h>

#include <Button.h>

#define CE_PIN 9 // Define radio pins

#define CSN_PIN 10 //

LiquidCrystal_I2C lcd(0x3F,20,4); // set the LCD address to 0x3F

for a 20 chars and 4 line display

const byte slaveAddress[5]

= {'R','x','A','A','A'}; // Set 'slave' or remote address

RF24 radio(CE_PIN, CSN_PIN); // Create an instance of 'radio'

char dataToSend[2]; // Data to be sent to remote unit

int

ackData[2]; // Holds the value coming from the remote unit

bool

newData = false;

char onOffMsg[12]{"Camera: OFF"}; // ON or

OFF message to be sent initially to display

int temperature;

int sendTemp = 1; // Ask for temp from slave? 1 = yes, 0 = no

int

justPressedButton = 0; // Indicator of just-pressed button; 1 or 2

int lastSentButton = 2; // Indicator of most recently pressed

button; 1 or 2 = ON or OFF

Button buttonOn2 =

Button(2,PULLUP); // ON/OFF button on pin 2; PULLUP so pin 2 does

not 'float'

//===============

void setup() {

Serial.begin(9600);

Serial.println("PanelCam TX starting ...");

lcd.init(); // initialize the lcd

lcd.backlight(); // turn

on backlight

initializeDisplay(); // Display the opening

screen (function)

radio.begin(); // Turn radio on

radio.setChannel(108); // Above most Wifi Channels

radio.setDataRate( RF24_250KBPS );

// Set the PA Level to

prevent power supply related issues and/or overpowering units

//

in close proximity. RF24_PA_MAX is default.

// radio.setPALevel(RF24_PA_MIN);

// Uncomment for minimum power

// radio.setPALevel(RF24_PA_LOW);

// Uncomment for low power

radio.setPALevel(RF24_PA_HIGH); //

Uncomment for high power

// radio.setPALevel(RF24_PA_MAX); //

Uncomment for maximum power

radio.enableAckPayload();

radio.setRetries(3,5); // delay, count

radio.openWritingPipe(slaveAddress);

// Initialize temperature on display //

send();

temperature = ackData[0];

showData();

} // End of setup

//=============

void loop() {

getButtonPress(); // get

button press

} // End of void loop //

//================

void send() {

bool rslt;

rslt =

radio.write( &dataToSend, sizeof(dataToSend) );

// Using sizeof()

as it gives the size as the number of bytes.

if (rslt) {

if (

radio.isAckPayloadAvailable() ) {

radio.read(&ackData, sizeof(ackData));

newData = true;

}

else {

Serial.println(" Acknowledge but

no data ");

}

}

else {

Serial.println(" Tx failed");

}

} // End of send function

//=================

void

getButtonPress(){

// Get button press data and assign it to 'dataToSend'

variable

// test for button press on pin 2 (ON/OFF button) //

if(buttonOn2.isPressed()){

Serial.print("lastSentButton = ");

Serial.println(lastSentButton);

if(lastSentButton == 2){ //

If OFF sent last then ...

strcpy (dataToSend, "1"); // Switch as

though ON button has been pressed

strcpy (onOffMsg, "Camera: ON

");

send();

showData();

Serial.print("dataToSend = ");

Serial.println(dataToSend);

Serial.print("onOffMsg = ");

Serial.println(onOffMsg);

}

if(lastSentButton == 1){ // If ON

sent last then ...

strcpy (dataToSend, "2"); // Switch as though

OFF button has been pressed

strcpy (onOffMsg, "Camera: OFF");

send();

showData();

Serial.print("dataToSend = ");

Serial.println(dataToSend);

Serial.print("onOffMsg = ");

Serial.println(onOffMsg);

}

if(onOffMsg[9] == 'N'){

lastSentButton = 1;

}

if(onOffMsg[9] == 'F'){

lastSentButton = 2;

}

Serial.print("New LastSentButton = ");

Serial.println(lastSentButton);

Serial.println("------------------------");

}

delay(200);

} // end of getButtonPress function

//=================

void showData() {

if (newData == true) {

temperature = ackData[0];

updateDisplay(); // Display temperature

on LED display

newData = false;

}

} // End of showData

function

//=================

void updateDisplay(){ //

Updates the data shown on the LCD display

lcd.setCursor(0,0);

// Line 1 - Header

lcd.print("Switch Status ...");

lcd.setCursor(0,1); // Line 2 - switch state

lcd.print(onOffMsg);

lcd.setCursor(0,3); // Line 4 - Temperature

lcd.print("Temp:

");

lcd.print(temperature);

lcd.print(" F");

} // End

of updateDisplay function

//=================

void

initializeDisplay(){ // Initializes the LED display with openinf

screen at startup

lcd.setCursor(0,0); // Line 1 - Header

lcd.print("PanelCam Switcher");

// Line 2 - Blank - for future

use

// Line 3 - Blank - for future use

// Line 4 - Blank - for

future use

delay(1000);

} // End of initializeDisplay function

//====== END ==========

|

|

Code for the Receiver:

// PanelCam Switcher RX using AckPayload - the slave

or the receiver //

// By Steve Schmeck 1-22-2017 //

#include <SPI.h> // radio interface

#include <nRF24L01.h> // for

radio

#include <RF24.h> // for radio

#include <OneWire.h> //

for temp sensor

#include <DallasTemperature.h> // for temp sensor

#include "LowPower.h" // power-saving

#define CE_PIN 9

#define CSN_PIN 10

const byte thisSlaveAddress[5] = {'R','x','A','A','A'};

RF24 radio(CE_PIN, CSN_PIN); // Create an instance of 'radio'

char dataReceived[10]; // this must match dataToSend in the TX

int ackData[2] = {109, -4000}; // the two values to be sent to the

master (placeholder numbers)

bool newData = false;

#define

ONE_WIRE_BUS 3 // sensor data line connected to Pin 3

OneWire

ourWire(ONE_WIRE_BUS); // Set up a oneWire instance to communicate

with any OneWire device

DallasTemperature sensors(&ourWire); //

Tell Dallas Temperature Library to use oneWire Library

int

remTemp; // int variable for sending temperature (remote

temperature)

//==============

void setup() {

Serial.begin(9600);

Serial.println("PanelCam RxAckPayload

Starting");

radio.begin(); // Turn radio on

radio.setChannel(108);

// Above most Wifi Channels

radio.setDataRate( RF24_250KBPS ); //

RF24_250KBPS for 250kbs, RF24_1MBPS for 1Mbps, or RF24_2MBPS for

2Mbps

// Set slow to assure reliability

// Set the PA

Level to prevent power supply related issues and/or overpowering

units

// in close proximity. RF24_PA_MAX is default.

//

radio.setPALevel(RF24_PA_MIN); // Uncomment for minimum power

//

radio.setPALevel(RF24_PA_LOW); // Uncomment for low power

radio.setPALevel(RF24_PA_HIGH); // Uncomment for high power

//

radio.setPALevel(RF24_PA_MAX); // Uncomment for maximum power

radio.openReadingPipe(1, thisSlaveAddress);

radio.enableAckPayload();

getTempFromSensor(); // get initial

temp from sensor & assign it to ackData

radio.writeAckPayload(1,

&ackData, sizeof(ackData)); // pre-load temperature data

radio.startListening(); // Power Note: this uses ~ 50 mA

pinMode(2,OUTPUT); // set pin 2 to activate relay

digitalWrite(2,LOW);

// set pin 2 LOW (camera is OFF)

}

// END of setup

//==========

void loop() {

getTempFromSensor();

LowPower.idle(SLEEP_2S, ADC_OFF, TIMER2_OFF, TIMER1_OFF, TIMER0_OFF,

SPI_OFF, USART0_OFF, TWI_OFF);

// Enter power down state for

4 seconds with ADC and BOD module disabled - not currently enabled

// LowPower.powerDown(SLEEP_4S, ADC_OFF, BOD_OFF);

getData();

showData();

Serial.println(dataReceived);

// DO

something with the data

if(dataReceived[0] == '1'){

Serial.println("got to dataReseived");

digitalWrite(2,HIGH); //

set pin 2 HIGH (camera is ON)

}

if(dataReceived[0] ==

'2'){

digitalWrite(2,LOW); // set pin 2 LOW (camera is OFF)

}

// END of Do Something

}

// END of void

//============

void getData() {

if ( radio.available() ) {

radio.read( &dataReceived, sizeof(dataReceived) );

//

updateReplyData();

newData = true;

}

}

// END of getData

//================

void showData() {

if (newData == true)

{

Serial.print("Data received ");

Serial.println(dataReceived);

Serial.print(" ackPayload sent ");

Serial.print(ackData[0]);

Serial.print(", ");

Serial.println(ackData[1]);

newData =

false;

}

}

// END of showData

//================

void getTempFromSensor() {

// Get temperature from sensor

sensors.begin(); // Start up the DallasTemperature library

sensors.requestTemperatures(); // Send the command to get

temperatures

remTemp = sensors.getTempFByIndex(0);

ackData[0]

=remTemp;

radio.writeAckPayload(1, &ackData, sizeof(ackData));

// load the payload for the next time

} // END of

getTempFromSensor

|