Trailer Mover - 11/30/2017

Trailer Mover - 11/30/2017

This is the first of what I hope will become a series of projects that produced a tool or process that has

worked for us. For some time I had wanted an easier way to move our two trailers around without endangering

my back or having to hook them up to one vehicle or another.

I had seen a couple of possibilities on the Internet and got some ideas then headed out to the shop.

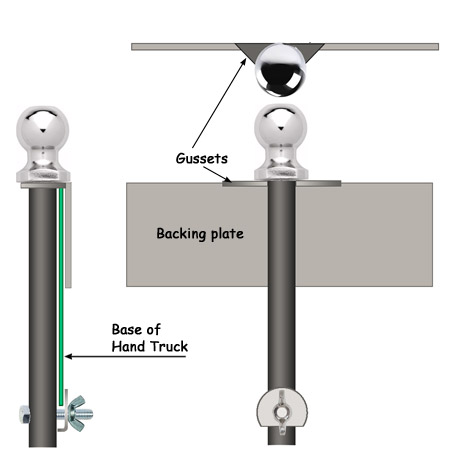

Using an old, 1-7/8” hitch ball, some scrap steel (a piece of an old, large saw blade and a short

piece of ¾” ID steel tube), our 40-year old hand truck and here’s what I came up with.

The whole rig is based upon using that old hand truck without making any alterations to it.

The unit’s backing plate (the saw blade part) slides down over the bottom of the hand truck’s

base plate with the tube running on the top side. There is a large fender washer on a ¼” bolt that

secures the bottom of the tube with a wing nut.

Building sequence:

1) I brazed the shaft of the ball into the end of the steel tube.

2) The backing plate was brazed onto the bottom flange of the ball, spaced out a bit more than

the thickness of the hand trucks base plate.

3) Two triangular gussets were brazed between the ball flange and backing plate to strengthen

the unit.

4) I drilled a ¼” hole through the lower end of the tube, just below the lower edge of the

hand truck’s base plate.

5) The fender washer was bent and shaped to fit the side of the tube.

Here is a drawing of the unit. Hopefully it will make some sense of the above.

In use I slip the ball under and into the trailer coupler and lowering the handle of the hand truck to

raise the tongue.

I can then wheel the trailer around easily, parking it in a back corner of the garage or whatever.

I have not tried to move any really heavy loads but this unit easily handles our 150 lb. boat on its trailer.

This tool is especially handy when parking the trailers inside for the winter, stuffing one in a corner of the

storage building and kind of nesting the other tightly beside it.

Homestead Electronics -- PanelCam: Installment #1 -- 12/27/2016

Homestead Electronics -- PanelCam: Installment #1 -- 12/27/2016

One of the realities of powering our homestead in the north-woods with power from the sun is that in the

winter there will be

times when the solar array is covered with snow. Even a light dusting can make a significant reduction in power production.

An inch of snow will effectively shut the panels off.

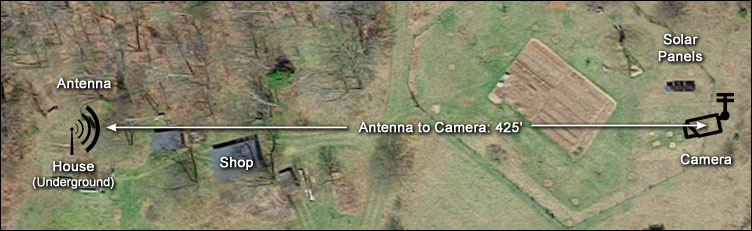

The obvious solution is to hike on out to where you can see the panels – they are about 400 feet from the house –

and if they are snow-covered gently scrape them clear with our handy-dandy long handled, foam-edged panel scraper.

Often, however, we get out where we can see the face of the array only to find that they are clear. Not a big thing,

really, just a brief snowshoe hike for the exercise.

This is all setting the scene for my current project: a Wi-Fi camera mounted out in the garden area, facing the array.

The camera will, upon request, fire up and transmit a nice clear image of the panels back to any device hooked up to

our home network.

Bill of materials (Specifications):

- Outdoor Wi-Fi Video Camera - (9 – 12 Volts DC powered, removable antenna)

- Wi-Fi Range Extender - (DC powered, removable antenna)

- “Cantenna” Wi-Fi Directional Antenna – (Homemade, increases signal ~12 dB (~400%))

- DC to DC Power supplies for both camera and extender

- Small Lead-Acid Battery to run the camera

- Two Arduinos with Wi-Fi units configured to turn camera on/off to save battery power

- Low-loss antenna cable & misc. wiring for powering all units

Are we done yet? Actually, all these items are readily available on-line and not terribly expensive.

The Cantenna’s main component is a tin can about 3-1/2” in diameter and 6” tall (empty).

The parts are ordered, except for the ‘can’, and the fun will begin soon.

To be continued!

----------

Homestead Electronics -- PanelCam: Installment #2 -- 2/7/2017

Homestead Electronics -- PanelCam: Installment #2 -- 2/7/2017

Well, the 'Array-Cam' is finally up and running. Click a

switch, push a button and check the snow conditions out on the solar array

on a computer or tablet "...in the comfort of your own home". Of course,

many days we get to hike out and clear the snow off the panels but mostly

is just fun to see what's happening out there. The photos below are:

Antennas mounted on the house roof, Camera box and its solar panel, Front

and back of the camera switch circuit board and finally, the view from the

camera.

(February 19, 2017 Update)

I have including details of this project including a few more photos and

Arduino microcontroller code on a new web page. Click for the complete

'PanelCam' article.

Homestead Electronics – Arduino - 12-5-2016

Homestead Electronics – Arduino - 12-5-2016

And you thought that I hibernated all winter! I have been amusing myself this fall/winter by

designing and building small electronic gizmos based upon Arduino

microcontrollers. This all started, as many homestead projects do, with

being frustrated by the fact that neither our solar charge controller nor

inverter can handle diversion loads.

There are many times, in all seasons, when the sun is out bright and the

batteries are fully charged. Sometime this happens early in the day and

the potential energy from the solar panels for the rest of the day is

just wasted. The charge controller sees that the batteries are full and

says, "I'll do my job of protecting the batteries from overcharge by

reducing the power I'm sending to them".

If we are around and

notice that the controller has been in float mode a while, we can

manually turn on a one or two circuits that power electric heating

panels. This has the potential to reduce the amount of firewood we burn

- a good thing.

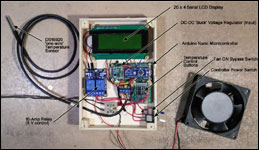

So, back to the electronic things. I am

designing a pair of circuits that sense battery voltage and charge

current and some software that runs on an Arduino that will turn on/off

relays that control those two heating panel circuits. I think I forgot

to mention that I have not always had a lot of luck with electronic

stuff. I have smoked many a home-made device. I figured that with that

background I’d start with something a little simpler; an Arduino-operated

greenhouse fan controller. This sort of thing is commonly known as a

‘thermostat’. Wheel reinvented!

Here’s what the fan controller

looks like inside…

All kinds of fun components and wires seemingly running everywhere! By

the way, it works just fine. The display shows the current temperature

as well as upper and lower set-points, which are adjustable. The unit

has been working well for a few weeks now. No smoke at all!

More

on the main project as it evolves… Steve.

Temporary Storage using Straw

Bales and some boards and plastic sheet

The articles, discussions, and books on straw bale building have been fun and

intriguing. If we build again, it is a technique we will certainly look into. But it is an

idea that can be used on a less formal scale as well, for temporary storage and shelter.

When we first moved to our current homestead, we discovered, to our surprise and dismay,

that one summer was not long enough to build a complete homestead -- not even a complete

house -- not even close. We also discovered that those unanticipated odds and ends drained

a limited savings even faster than the grasshoppers devoured the new garden, planted on

worn-out soil. Fall arrived with the house built up only as high as the footings. We

looked around and made the responsible decision to move back down to the city to work for

money for a few more years (which lasted two months before instinct overruled supposed

responsible action, and we moved back to the homestead).

But all our worldly goods were residing under a large sheet of heavy black plastic, where

we had unloaded them from the moving van that spring, and had laid them out in more or

less organized rows for their temporary stay until we got the house done that summer. So

we thought. But now, it didn't seem the best storage facility for a longer duration. And

besides, the thrill of crawling under that black plastic to find the particular box that

had that one item in it that we wanted had long faded away. A neighbor down the road was

baling straw about then. Ah hah!

We bought enough bales of straw to stack, one over two, into a building eight feet wide on

center by about twice that long, with an opening in one wall for a door. For the roof we

had the eight foot rough wood forms we had made for the footings and walls of our planned

house (ala Nearing slip-form type stone and cement wall, which later turned into an Oehler

PSP wood type). We set the heavy forms, made of rough pine 2-by-4s and 1-by-6s, on the

straw bale walls and covered the whole thing with the piece of 10 mil black plastic that

had been covering our belongings. Scrap boards laid on the plastic kept it from blowing

away.

What a great improvement! What luxury! It was something we should have done at the very

first. This hay bale temporary storage building lasted for many years, and the chickens

that came the next year loved to scratch around the base of the straw walls. When we built

a more permanent wooden storage building, the straw went to good use on the garden, and

the plastic and forms went on to other lives.

As is the way on the homestead, many of those wooden forms were used a few years later as

a roof on a "temporary" lean-to off the wooden storage building -- for

rototiller, corn grinder, tires, and the like. Last year the "temporary" lean-to

(probably twelve years old) was replaced with a "real" addition (2-by-10

rafters, metal roofing, walls made of salvaged used metal garage doors). The best of the

forms became a new porch off the woodshop (former cabin). The rotten ends of the worst

were sawn off, the remaining halves used as scaffolding for building a new hangar. And

life on the homestead goes on -- for people and materials.

* * * * * *

Copyright

© 1999 by Susan Robishaw

* * * * * *

Copyright

© by Susan Robishaw and Stephen Schmeck