|

Introduction:

[March 18,2023]

This will be our fifth skin-on-frame boat build. Although the photo above looks somewhat like a

smaller version of our Chamberlain Gunning Dory it is a totally different design also by Dave Gentry.

As designed his 'Ruth' high performance wherry would be 18' long with a beam of 33" and could weigh

as little as 45 lbs. Our slightly modified version will be 16' long and will have an inch more freeboard

(depth).

I've made these changes for a couple of reasons. Length: 1)We have found

that 18' boats are a bit longer than is easy to store in our boat shed.

2) Shorter means lighter, and 3)rowed/paddled boats 16' or less don't need to

be registered in Michigan. It seemed prudent to add a little depth to the

hull for safety while rowing on Lake Michigan and because of the slight

reduction in buoyancy caused by shortening the boat.

One other minor change will be the use of heavier, 13 oz. polyester fabric

rather than the specified 8 oz. material. As it turns out that lighter

fabric is no longer available from George Dyson or any of the other sources

I've researched. This 13 oz. fabric is the same as the material we used to

cover our dory back in 2015 and it has held up really well.

[March 30, 2023]

We have had a few nicer days with daytime temperatures predicted up into the

upper thirties so I fired up the woodstove in the boat shop and got to work.

I have ripped out all of the long pieces; gunwales, inwales, chines & keel,

and have made the 7:1 scarf cuts so they are ready to be glued end-to-end to

make them 18' long.

The wood I'm using is Radiata pine, the nicest knot-free wood available in

the area. It is a little heavier, stiffer and stronger than the specified

western red cedar so all these stringers have been scaled down in

cross-section about 25%. This should allow the stringers to bend more easily

yet still be at least as strong as if they were red cedar.

[March 31,2023]

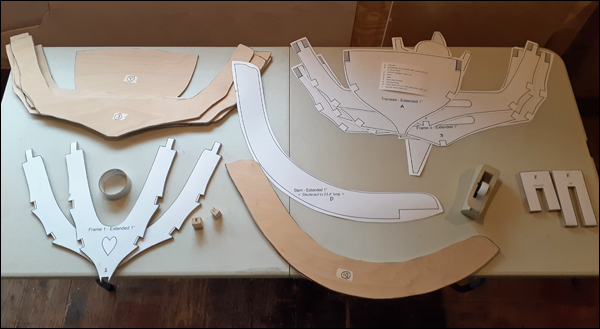

I cut out the individual parts on the full-sized printed plans, laid them out

and traced them on some 1/4" Baltic Birch plywood. They are all now roughly cut out with a

scroll saw and ready to be cleaned

up on the band saw. A nice cozy 55° in the shop today.

I also laminated two stem pieces so the finished stem is 1/2" thick per the

plans.

[April 1, 2023]

We got over 7" of heavy, wet snow last night so I

spent quite a while shoveling which meant a late start in the shop this

morning. By the end of the day I had all of the frames cut out to their

final size and shape and began the process of getting each frame ready to be

placed on the strongback for assembly.

The plans called for the frames to be made from 1/2 marine plywood -

something not available locally. Dave Gentry says it is OK to substitute

when necessary so I've come up with something that is admittedly not normal

for this sort of thing but here it is:

As I mentioned above, the frames are cut out of 1/4" Baltic Birch plywood

and I am adding reinforcement pieces at all points where the gunwales,

chines and keel meet the frames. This will give me a 1/2' thick spot to

screw and glue each joint and generally strengthen the frames. I could have

just cut out a second set of frames and laminated them to be 1/2" thick but

they would be quite a bit heavier than my new system. Those little

reinforcement pieces (all 42 of them) were cut out of scrap. I knew I'd kept

all those little chunks of plywood for something.

[April 13, 2023]

We have had some nice warm spring days and

most days I have been working on the boat. The individual frames are

completed and set up on the strongback. Today Sue noticed that it looked like the rowing seat was quite far forward

so I did some research and measured the expedition rowboat and decided to

move the center three frames around a bit to get the rower's weight in a

more balanced position. The frames that support the seat are now about 6"

toward the back of the boat and I extended the space where your legs & feet

go by about 2 more inches. Overall I like the look of the boat in this new

configuration. The widest part of the boat is somewhat farther aft and that

should make it easier to steer. In the photo the bottom half of the gunwales

are just clamped in position. The next step is to screw and epoxy them

permanently in place and then laminate on the upper halves. The laminated

gunwales will be stronger and help the boat keep its shape. Clicking on any

of the images should give you a larger photo.

Today Sue noticed that it looked like the rowing seat was quite far forward

so I did some research and measured the expedition rowboat and decided to

move the center three frames around a bit to get the rower's weight in a

more balanced position. The frames that support the seat are now about 6"

toward the back of the boat and I extended the space where your legs & feet

go by about 2 more inches. Overall I like the look of the boat in this new

configuration. The widest part of the boat is somewhat farther aft and that

should make it easier to steer. In the photo the bottom half of the gunwales

are just clamped in position. The next step is to screw and epoxy them

permanently in place and then laminate on the upper halves. The laminated

gunwales will be stronger and help the boat keep its shape. Clicking on any

of the images should give you a larger photo.

[April 26, 2023]

I have been working on the boat pretty regularly

and it is coming along fine. In this photo you can see that the gunwales and stringers are securely glued in place and I am

gluing on one of fifty (50) 2" x 1¼" cedar blocks evenly spaced along the

inside edge of the gunwales. Once the glue is dry I'll begin adding the

laminated inwale pieces to complete that structure. This creates a very

strong and stable sheer of the boat. Boat building is sharing time

with spring chores. We're heading into a bit of a rainy period so things

should progress a little more quickly.

can see that the gunwales and stringers are securely glued in place and I am

gluing on one of fifty (50) 2" x 1¼" cedar blocks evenly spaced along the

inside edge of the gunwales. Once the glue is dry I'll begin adding the

laminated inwale pieces to complete that structure. This creates a very

strong and stable sheer of the boat. Boat building is sharing time

with spring chores. We're heading into a bit of a rainy period so things

should progress a little more quickly.

[ Back to Top ]

[June 10, 2023]

Well, it has been entirely too long since I've

posted an update here. As usual this time of the year I've been splitting my

time between boat building, homestead projects, biking, and even

a bit of rowing. As of today the frame has been completed, sanded, oiled and

skinned. Today's project is to finish shrinking out any remaining wrinkles

with my 'shop iron' set on high and then putting on the first coat of

water-based spar polyurethane varnish. I'll follow up with at least two more

coats and then begin painting. The decision to paint the boat rather than

leave it translucent was settled by having smashed a full mosquito on the

fabric - not

pretty! At any rate, here are a few photos of the frame before skinning and

one in the skinning process. Click on any image to see it

enlarged.

[June 14, 2023]

A couple of days ago I applied two coats of water-base polyurethane varnish

as primer to the hull and today put on the first coat of 'Essence of Green'

(pale green) acrylic latex porch and deck paint. It looks good but will

probably need a couple more coats both for protection and waterproofing and

to even out the opaqueness.

It is possible that the boat will be ready to launch by the 4th of July!

[ Back to Top ]

[June 26, 2023]

After putting on a few coats of that pale green paint Sue advised me that it

was just too pale so I bought some slightly greener paint and I have to

admit that it does look better. Being red-green color blind doesn't make

these decisions real easy so I do appreciate Sue coming to the rescue. I

think I have three, maybe four coats of the new color on and the painting is

done.

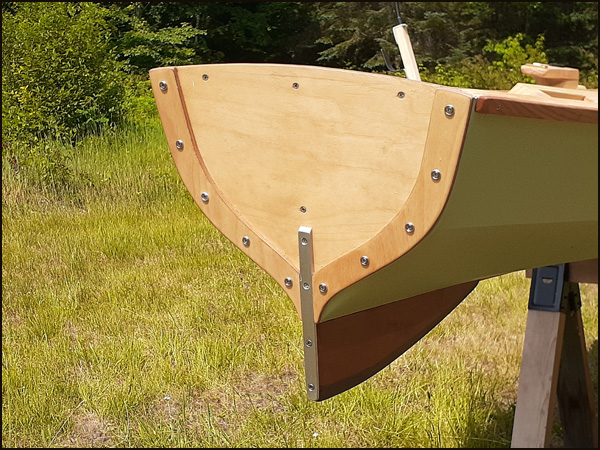

The first photo shows the laminated oak stem protector temporarily in place

and the second shot is of the skeg trial-fitted.

shot is of the skeg trial-fitted.

The way most builders of this design finish the transom is to wrap the

fabric over the edge a couple of inches and staple it in place. Then they

fold an inch or so of the fabric back over to hide the staples and fasten

that in place with upholstery tacks. I didn't really like the look so came

up with my own system - as usual. I just sawed out a couple of pieces of

1/4" plywood the shape of the outside edges of the transom and refined the

shape a bit to have them cover the fabric and two rows of staples. They are fitted around the aluminum skeg stabilizer and held in

place by stainless steel screws with finish washers - similar to those on

the stem. It looks cleaner to me and is serviceable if needed.

staples. They are fitted around the aluminum skeg stabilizer and held in

place by stainless steel screws with finish washers - similar to those on

the stem. It looks cleaner to me and is serviceable if needed.

We flipped the boat over and I spent today fitting the gunwale rub

strips that both protect the edge of the boat and hide the staples that hold

the fabric in place. Those pieces and the keel rub strip are made from 1/4"

x 3/4" unfinished oak 'screen molding'. It looks nice and being oak is very

durable. The transom was varnished back when I put the first coats on the

fabric but all other wood is treated with tung oil. This worked out well on

our other boats and is especially nice because it is so easy to touch up.

.

[July 4, 2023]

Made it! - sort of, anyway. I was hoping to launch the boat by the 4th of

July although it is ready to go the weather didn't cooperate. It was 86° here this afternoon -

just too hot to enjoy being out on the water. The forecast is for a couple

of days of rain, which we will enjoy, then a couple of days with

temperatures in the 70's. I console myself knowing that these hot, dry days

ensure that the paint is drying well.

ready to go the weather didn't cooperate. It was 86° here this afternoon -

just too hot to enjoy being out on the water. The forecast is for a couple

of days of rain, which we will enjoy, then a couple of days with

temperatures in the 70's. I console myself knowing that these hot, dry days

ensure that the paint is drying well.

Speaking of paint, I suppose the project isn't really completed until I get

a coat of paint on

.

the new wooden trailer/boat interface.

I'll get some better photos soon. In the mean time, the I'll be cleaning and

reorganizing the shop. It is amazing how small the shop looks and feels

while a boat is in there and how big and bare it looks now.

| Here are some photos of the boat just before it was launched: |

Breast hook |

Transom

|

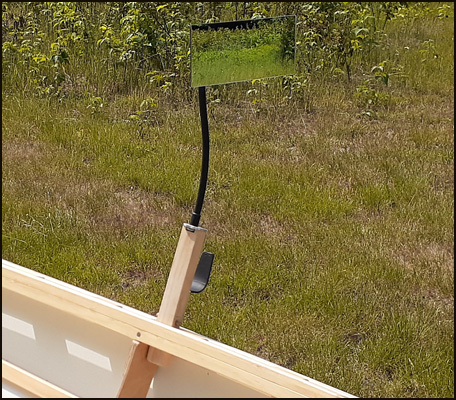

Mirror assembly |

Riggers with fixed seat |

Riggers with Sliding Seat |

Sliding Seat Detail |

And now the boat has a name, "Lilli B" (short for

Lilli Bulero, our calico cat).

I burned the name and image with my trusty pyrography tool.

[ Back to Top ]

|